How to solve gluing not well problem

Introduction: in order to make the color box packaging more beautiful and low-cost on the basis of fully displaying the product characteristics, many color box user enterprises have formulated strict standards for the packaging specifications and quality, and put forward strict requirements and detailed standards for the whole production process of pre press, in press and post press processing of color box to the suppliers. The post process, especially the paste process, which determines the quality of color box products, is the key production link.

What are the advantages of automatic paste box?

Paste box is the key link of carton forming. According to different processing methods, paste box production can be divided into manual operation and automatic production.

Manual paste box, is the operator according to the requirements of the design, hand glue on the flap, and then compaction to complete the flap bonding to form the desired carton.

At present, the manual box pasting method is mainly used in some high-end high-quality packaging boxes and some box types that can not be processed by the box pasting machine, such as the cartons with short box pasting line and long box length. The paste quality of these cartons is unstable, and the “trumpet” phenomenon often appears.

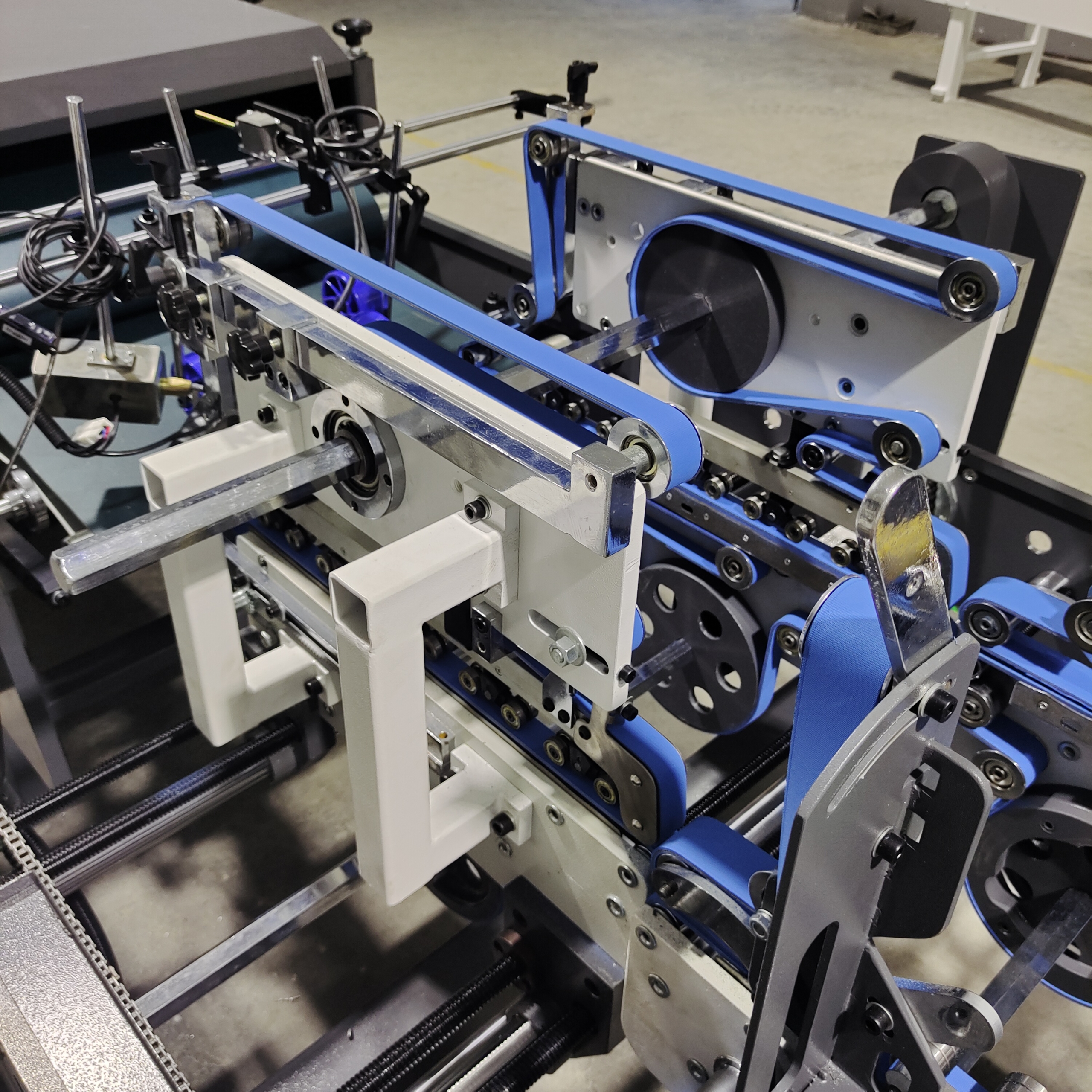

The basic process of automatic paste box production is to put the die-cut cardboard on the paste box machine, and form it after separation, pre folding, gluing, folding and compaction.

Compared with manual box pasting, automatic box pasting machine has the advantages of simple operation, firm bonding, high efficiency, stable quality and accurate counting, which can meet the fierce market competition, so it has been paid more and more attention by the industry.

However, in the process of automatic box pasting, a variety of technological problems and mechanical failures easily lead to product quality problems.

Causes and solutions of common problems in paste box

In the process of pasting box, the common problems are low fastness, carton degumming, carton deformation, and skew adhesive mouth. The main reasons for these problems are as follows

Reason 1: the viscosity of the adhesive is not enough, the amount of glue is not enough or it is not suitable for the carton material.

Solution: for the paste box caused by adhesive is not firm, should choose and paste the carton material to adapt to the adhesive. Pay attention to its viscosity and temperature.

Reason 2: the adhesive is difficult to penetrate through the surface after coating, glazing and other surface treatment.

Solution: for the coated and polished carton, there are many ways to solve the problem that the paste box is not firm.

During die cutting, a needle knife is placed at the adhesive mouth to puncture the surface layer of the adhesive mouth, or the surface layer of the adhesive mouth is abraded by the edging device attached to the automatic box pasting machine, so as to facilitate the penetration of the adhesive.

The hot melt adhesive is sprayed on the sticking part, and the material on the sticking surface is melted at high temperature to improve the firmness of the paste box.

Prepress box design, can be in advance to film and polish the edge of the box to leave gelatinized parts.

The third reason is that the pressure is not enough and the pressure time is not long enough after folding and gluing, which is not conducive to sticking firmly.

Solution: for the phenomenon that the paste box is not firm due to insufficient pressure, you can increase the pressure of the pressing part of the paste box machine, extend the pressing time, or replace the adhesive with strong adhesion.

Reason four: die cutting accuracy is not high, adhesive water content.

Paste box is an important part of carton forming. Its quality is closely related to the die-cutting process. If the die-cutting is not good and the indentation is not deep enough, no matter how good the paste box equipment is, it is impossible to paste a good product. And die-cutting process in the production of die-cutting plate and this has an inseparable relationship.

The accuracy of die-cutting plate is not high, it is easy to lead to the inconsistency of carton sheet, the carton deformation when pasting the carton; when the moisture content of adhesive is high, it is also easy to lead to the moisture absorption deformation of paperboard, and the carton is uneven after forming.

Solution: pay attention to the adjustment of paste box machine in production. Reduce the groove width of the indentation steel wire, increase the indentation pressure; adjust the folding transmission to make the conveying speed of the left and right sides of the carton consistent, and pay attention to the installation and adjustment of the folding rod; avoid the sticking skew caused by insufficient indentation force, improper adjustment of the folding transmission and inconsistent conveying speed of the left and right sides of the carton.

Leave a Reply

Want to join the discussion?Feel free to contribute!