ZHANTIAN is ready to grow up in the field of packing machine

In 2021, FACHPACK, the leader of exhibition service providers in European packaging industry, released its TRENDRADAR 2021 REPORT. The white paper talked about today’s hot topics and future trends, and emphasized several emerging development directions in the next 3-5 years. We, ZHANTIAN, highly recognize the future development trend pointed out in the white paper, and will adjust and improve our products, folder gluer, in recent years to meet this trend and bring macro progress and improvement to the packaging industry.

1. Material

For the packaging industry, the choice of packaging materials is very important. Correct and appropriate materials can increase the added value of products; improper packaging will cause waste of resources and environmental damage. Therefore, we need to be rational and cautious in the selection of packaging materials.

1.1 Use of recycled materials

Increasing the use of recyclable materials is still within the scope of development trend and can be greatly changed. This view was put forward after investigation by insiders of the industry. Coincidentally, packaging act also proposed that 60% of plastic packaging must be recycled after dual system, which is a view with a very environmental protection concept. Increasing the market utilization of recyclable materials is a huge challenge because its price is much higher than that of “virgin” packaging materials.

In addition to the utilization rate of recyclable materials, the quality of materials should also be paid attention to. At present, there is no clear definition for the benign development of materials in the field of packaging in the world. This cannot reasonably protect the legitimate rights and interests of buyers. In this module, the first mock exam should be issued with a clear definition to ensure the orderly development of the packaging materials market.

As for PET materials, it looks better for recycled. Schwarz Produktion in Germany, especially for the Lidl and Kaufland private labels, makes all disposable PET bottles 100% recycled starting from June 2021. Each new bottle is produced from recycled old bottles. With the increase of plastic percentage recovery rate, the company can save 50000 tons of PET material every year. This has made a great contribution to global environmental protection and resource conservation.

The importance of increasing the use of recycled material is PE, PET and PP internationally recyclable. However, the proportion of materials and the limitations of value are difficult to define. In addition, the price of new materials is lower than the recycled ones. The other challenge is the waste of plastic.

1.2 Resource-saving package

The resources on earth are not inexhaustible. The formation of resources takes tens of thousands or even hundreds of millions of years, which is very precious. Human beings need to cherish energy. In the field of packaging, how to save resources to the greatest extent? First, in terms of packaging design, more consideration should be given to degradable materials or single materials. In other words, only one material composition is allowed on the packaging material. If multiple materials are needed, materials that can easily decompose into independent materials should be used. Manufacturers extract recyclable materials and process finished products to realize material recycling.

Fortunately, people have successfully separated different materials and recycled them. The development of material recycling is still relatively successful. MKL papers has developed a new type of double-sided film covering material, which can keep the interior dry and isolate moisture. It has strong impact resistance and avoids damage to articles during transportation. Its external surface has exquisite printing surface, which highlights the product characteristics and transportation precautions. The material is recyclable mono material.

According to the reported by Fleischaft in August 2021, the paper label and bottle cap cannot be returned to the material cycle, which is also important in the recycling process.

1.3 Circular Economy

Dr. Björn Moller, Fraunhofer Institute for Systems and Innovation Research ISI,said that Circular economy refers to the entire value chain. As a result, there will be a high demand for new cooperations in the future. One of the importance of cyclic economy is enterprises should do a good job in independent transformation and development. Every step of the enterprise’s planning should be rigorous and should not be extravagant and wasteful.

To achieve the goal of economic cycle, enterprises will face many challenges. The biggest challenge is to record all links in the product supply chain, such as raw material procurement, R & D, design and processing. Enterprises should clarify the direction of capital flow in each link. On the other hand, reduce the complexity of material variety, design and packaging. This is also a big challenge.

2. Production technology

In many fields, artificial intelligence has been widely used. With the popularization of artificial intelligence, the production efficiency of packaging machinery is also improving. But at the same time, it also brings a difficulty to enterprises, that is, the economic benefit of time. AI intelligence has long been applied to e-commerce platforms, such as Amazon, shoppee, Alibaba, etc. Taking Alibaba as an example, with the help of AI, the packaging of goods has entered the stage of sustainable development. AI can provide accurate packaging size according to the needs of each customer. In addition, the transportation damage rate will be reduced to 10%. Because the damage rate is reduced, the transportation fee is also reduced by 2%. This is good news for both buyers and sellers.

If enterprises want to use AI, they must first collect data and study many successful use cases to draw conclusions. AI not only brings cost control, but also quality assurance. In the quality inspection mode, AI carries out quality elimination according to the set procedure, with an accuracy of 100% and zero error. This is a height that is difficult to reach by manual detection.

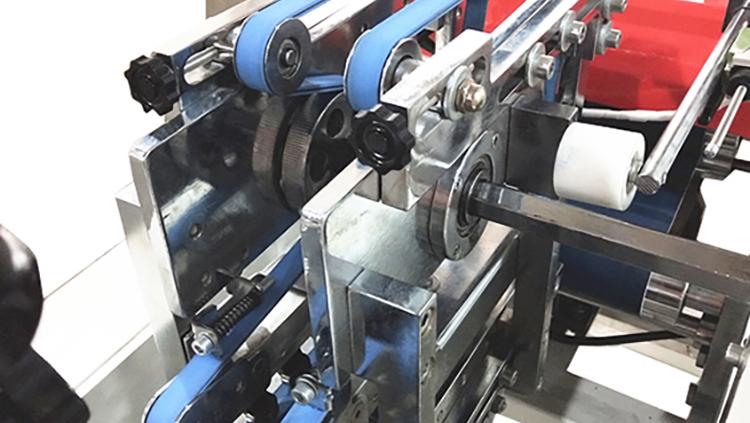

ZHANTIAN machinery company plans to introduce AI technology into the field of box pasting machine in the next 5-10 years. It is specifically used for machine adjustment between different box types. At this stage, the use of box pasting machine has encountered two biggest difficulties. It is very difficult to find local technicians. Second, for some difficult boxes, it is difficult for technicians to adjust to 100% accuracy, resulting in the box is not exquisite. If AI technology is applied to the operation of box pasting machine, these two problems will be solved. AI will automatically scan and identify each different box and material, calculate the corresponding box pasting method and adjust the machine to the best position. After the machine is adjusted, the worker can start production by clicking the start button. The worker can also set the automatic start mode. AI is an essential development trend in the field of folder gluer machine. Zhantian Machinery is willing to meet the difficulties and open up a new field for the packaging industry to a higher level.

3. Functional packing

Sustainable packaging tops the list of packaging trends. Researchers advocate recyclable materials, increase the proportion of recycled materials, reduce damage during transportation and improve package tracking technology.

3.1 High quality assurance

Active and effective packaging can reduce the damage caused by food transportation. Foam box, collision prevention column and sponge belt can play a very good protective role. Food has extremely strict requirements for temperature. It is necessary to maintain a certain temperature during transportation to ensure the freshness of food. At this time, ice bags are of great use. Ice bags are recyclable products, which is very in line with the concept of modern economic development and environmental protection.

With the use of ice bags and fresh-keeping bags, the transportation cost is bound to increase. This is an inevitable challenge. In addition, according to the terms, smart packaging developed overseas is not allowed to be used in other countries. This is a bottleneck in the development of packaging industry.

3.2 Package tracking technology

One package, one tracking, this is the vision of mankind for the packaging industry. How? The labeling on the package is a key step. Each package has its unique two-dimensional code or number, which can realize package tracking with the package management system.

The packaging industry can be expected in the future, and ZHANTIAN Machinery will make its best efforts to this end.

I will recomment it to my university project.

I need to to thank you for this great read!! I certainly loved every bit of it. I have got you book-marked to look at new things you post

Today a reader,tomorrow a leader!

Where there is a will, there is a way.

I’m a greener in folder gluer machine.

I benefit a lot. thanks

Thanks for sharing!

perfect blog. I love it