Solution of box folder gluer machines

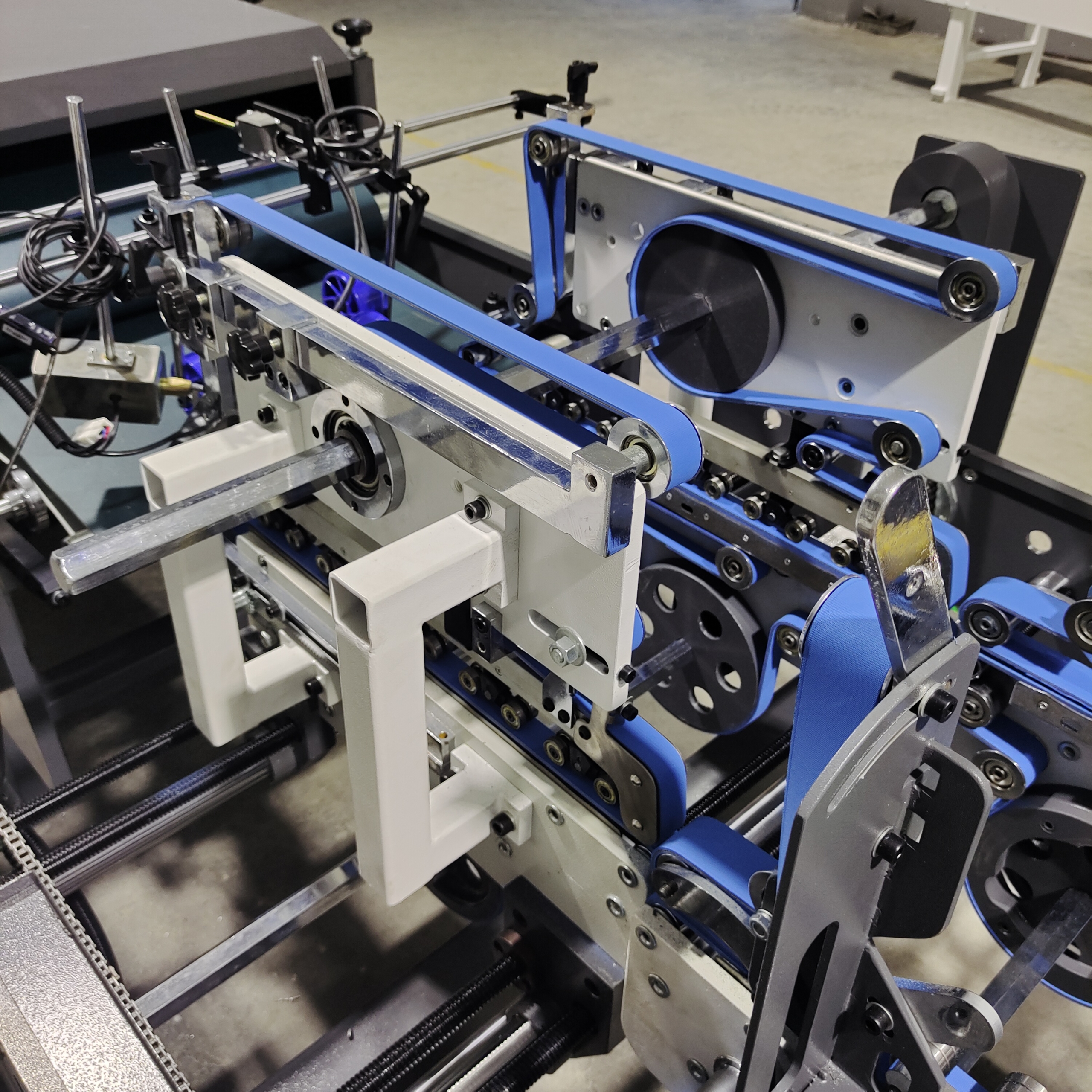

The machine structure of the automatic pasting machine is shown in the figure below, which can be divided into: paper output section – pre folding section – turn back section – hook bottom section – local folding section – pressing section – conveying section. Each section has two or four metal plates, and there is a metal roller under each plate. By controlling the position of each plate, the roller presses the carton at a specific position, so that the carton can be folded and bonded at a specific position, and finally sent out at the paper receiving section.

Technological requirements

- The target position of each board can be determined automatically according to different box types.

- For the undefined box type, that is, the user-defined box type, to make the machine self-learning, when the machine has learned the box type, it will automatically memorize the relevant parameters of the box type, so that the user does not have to input any parameters to process the box type again.

- All box parameters can be fine tuned during operation, and the fine tuned parameters will be automatically stored after fine tuning.

- The validity of the box type parameters input by the user can be checked. When the parameters input by the user are illegal, a prompt can be given.

- If the user adjusts the sensor position, the system parameters should be recalibrated.

- In the process of operation, if the equipment fails, it should be able to indicate which part and which point of the equipment the alarm occurs at.

Technological difficulties

- According to the output frequency detected by the electric eye, the conveying speed can be adjusted automatically. As shown in the figure below, because the paper output action depends on the belt friction, the distance between each carton is uneven, sometimes there is a long distance; if the conveying part runs at a fixed speed, when the distance is long, there will be a large gap, which is not conducive to the carton pressing and subsequent packaging.

- In high-speed operation, accurate water jet kick paper output. As shown in the figure below, when several cartons are produced, the paper kicking cylinder (or water spray head) should output once, and make a mark on the current carton to facilitate the subsequent counting work. Previously, this function was realized by the delay output after the electric eye has a signal, but due to the different incoming speed of the carton, this method has a large error and can not meet the needs of customers.

- The automatic storage and memory of box parameters makes it unnecessary for the user to input box parameters every time. When the user processes the previously processed box again, the user only needs to call out the corresponding box parameters. In addition, the system will automatically memorize the results of the last automatic calculation, so it is not necessary to deduce and calculate the box parameters before each positioning.

Leave a Reply

Want to join the discussion?Feel free to contribute!