Technique to adjust of high speed automatic folder gluer for lock bottom box

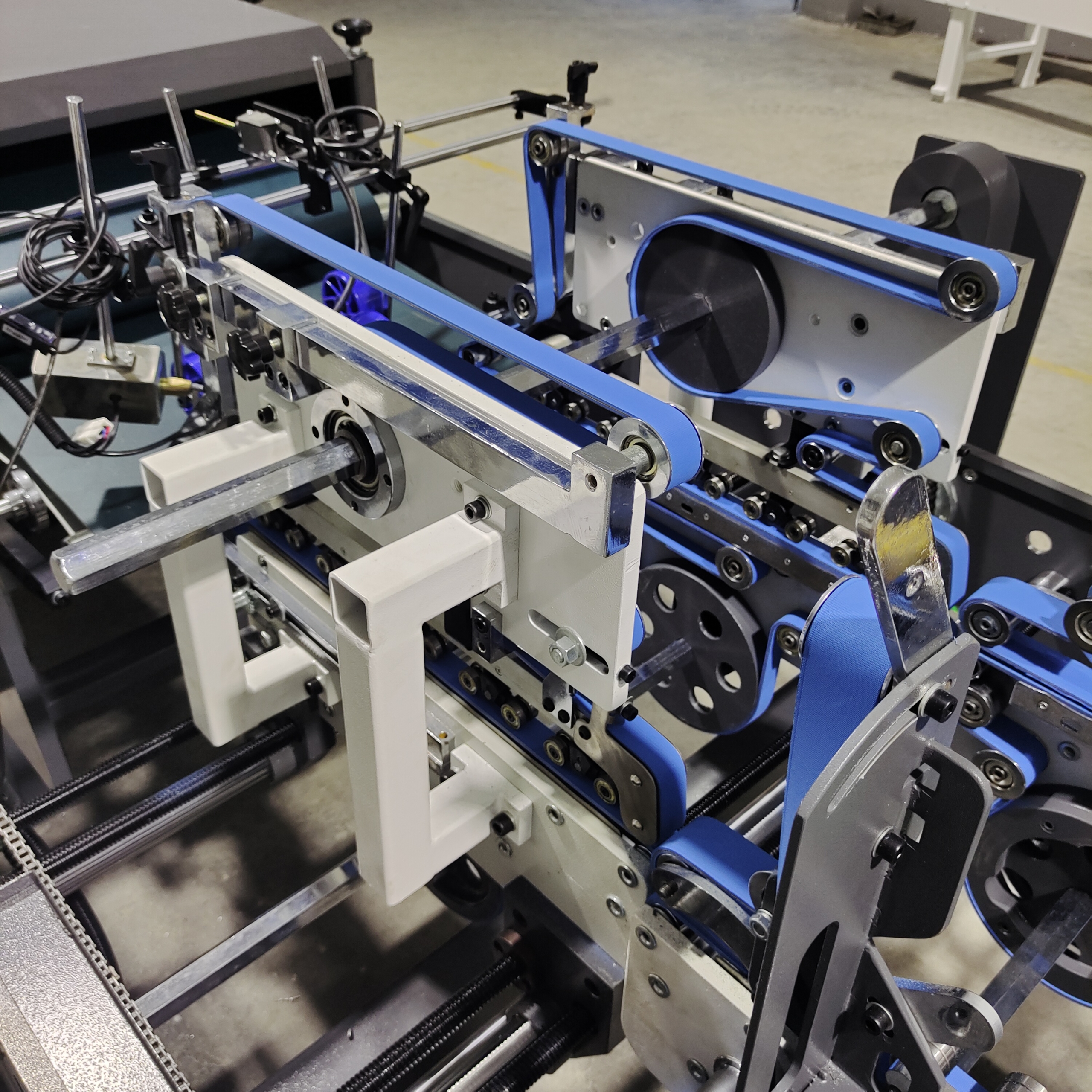

Purchasing new equipment is a happy thing, but the trouble that comes with it is how to operate the equipment? This article focuses on the adjustment skills applicable to the bottom box type. I will elaborate on the prototype of ZHANTIAN’s classic G series.

This type of folding box machine can complete two types of box pasting. One is side pasting box; the other is bottom pasting box. In terms of application, the side sticking boxes are widely used, and the current packaging boxes for daily necessities such as aluminum plastic plate drugs, toothpaste, cosmetics, etc. all use this type of box. Similarly, the bottom sticker box is irreplaceable for its unique advantages of bearing weight and being suitable for the use of automatic packaging lines. In terms of production, the modulation of the side stick box is relatively simple, while the modulation of the lock bottom box is relatively complex. Compared with the side gluing box, there are more adjustments to the pull up, bending, gluing and control of the box bottom, which are completed by the bottom stick part of the machine, as described below:

First, let’s understand the structure of lock bottom boxes.

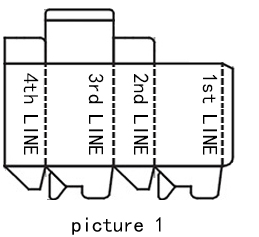

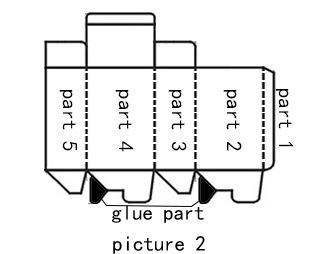

Picture 1 and Picture 2 are the plans of the bottom mounting box that we want to adjust. Through picture 1, we should know that the four vertical dotted lines of the carton respectively correspond to the first to the fourth polylines. The adjustment of the tape position of the pasting machine is based on these four broken lines. Picture 2 introduces the five sides of the carton, the bottom part of the carton and the gluing surface of the carton bottom. The first to fifth sides of the carton and the bottom of the carton indicate the specific installation positions of the components at the bottom pasting part of the carton pasting machine, and the gluing surface at the bottom of the carton is adjusted for the gluing device at the bottom pasting part of the folder gluer machine.

Secondly, recognize the names and adjustment standards of the accessories at the bottom part of folder gluer machine.

There are many accessories for lock bottom part operation, and their installation positions are different. In order to master the bottom pasting operation skills as soon as possible, you should remember the names, installation positions and use methods of various accessories. On the basis of mastering a box type bottom pasting skillfully, you can draw inferences from one instance to another. In order to change the box shape at will in the future, install various accessories in place quickly and accurately, and complete the pasting work of the bottom pasting box with high quality.

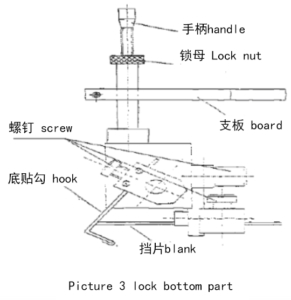

1. Lock bottom hook

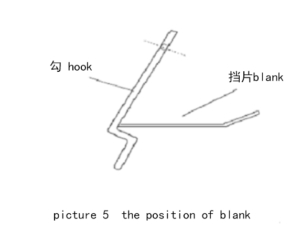

The lock bottom hook component is the most important component to pull up the bottom part of the box. It is fixed to the designated position of the machine by the support plate. Loosen the corresponding screws to adjust the height and angle of the hook and the position of the blank. The elasticity of the bottom hook can be adjusted by rotating the handle to adapt to cartons with different thicknesses. The lock nut is used to tighten the adjusted handle. There are requirements for the extension length, inclination angle and installation height of the hook (see Picture 4). The extension length of the bottom sticker hook is generally 1.2-1.5 times of the bottom length of the carton, and the inclination angle is 30-60 degrees. The bottom sticker hook angle should be 2-3 mm higher than the carton. The principle is to ensure that the cardboard is pulled up by the lock bottom hook when passing through, and that the cardboard can be safely unhooked after a certain time and distance.

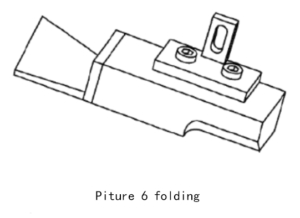

2. folding board

The folding board is used together with the lock bottom hook assembly. When the bottom of the cardboard is pulled up by the bottom hook, the pressboard (see Pic. 6) will press the paste part on the bottom of the lock bottom box forward. After the cardboard passes through the pressboard, it will be glued through the upper paste cylinder assembly and pressed firmly into the folding part by the paper bar.

The special paper pressing rod plays an indispensable role in the bottom pasting operation. The special paper pressing rod is used to prevent the bottom being pulled up and bent from springing up, so that it can enter the folding part smoothly and finally complete the pasting of the bottom sticker box.

Thirdly, installation position and adjustment requirements

1. installation position

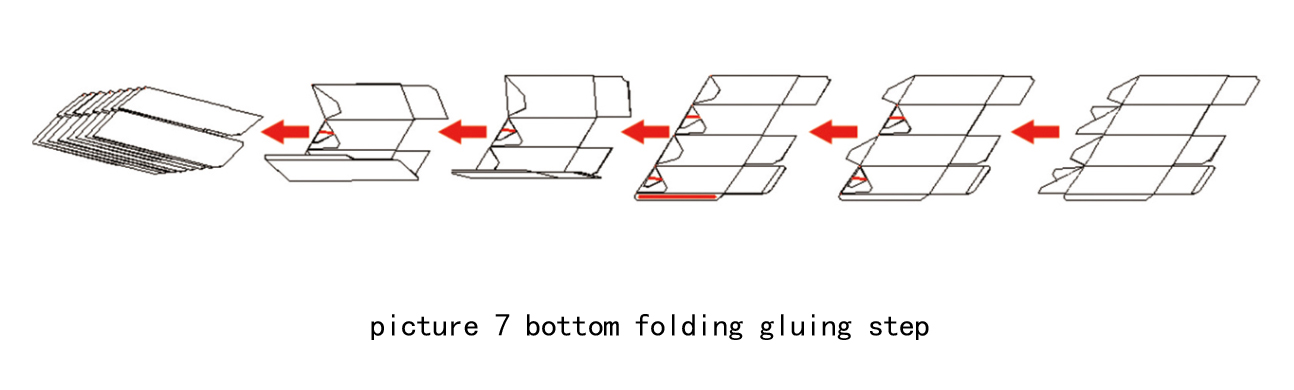

The first step is to determine the position of the folding belt at the bottom part. There are three rows of belts in total. The wire tape on the operation side shall be pressed on the first line of the bottom mounting box, and shall not be pressed over the first polyline; otherwise it will affect the pull up of the box bottom. The middle line belt is pressed on the third part of the bottom stick box near the third polyline, giving way to the position of the bottom hook on the third part. The cable belt on the drive side is pressed in the middle of the fifth part of the bottom mounting box. (See Picture 7)

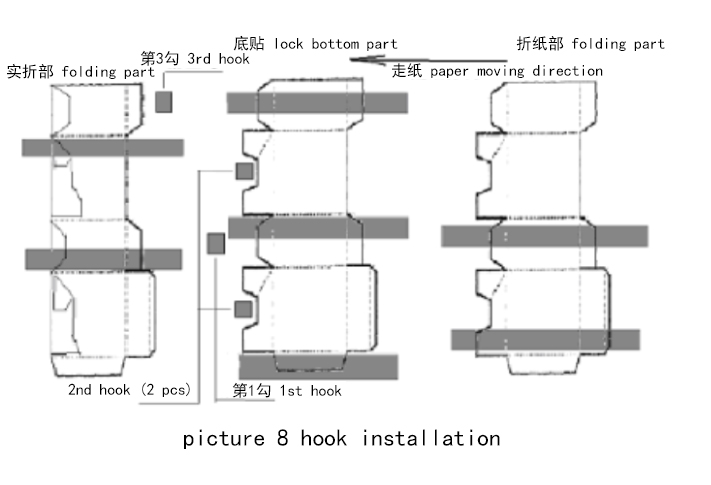

Second, we determine the installation position of the accessories of the bottom mounting part:

There are four groups of bottom hook components to be installed. The first hook is installed near the end of the folding part at the bottom of the machine, and the middle of the simple support beam is pasted on it. Pull up the bottom tongue on the third part of the lock bottom box. The second hook (two groups in total) is installed on the bottom stick bracket, which is located at the side of the pre folding part of the upper paste cylinder. It is used together with the bent cardboard. Its installation standard will be explained in detail below. The third hook is installed on the transmission side of the actual folding part close to the bottom pasting part. Pull up the tab on the fifth side of the carton. The installation positions of the four sets of bottom stickers are shown in Picture 8.

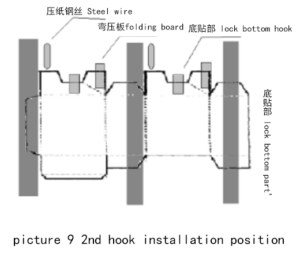

The installation of the first hook and the third hook is relatively simple. The second hook has two sets of bottom hook accessories, which also need to be used together with folding board. The machine is equipped with four sets of bottom hooks, four pieces of left and right pressboards, four pieces of width and four pieces of width respectively. In addition to correctly laying the cardboard and installing the bottom stickers according to the requirements of picture 9, select the wide or narrow folding cardboard according to the size of the paper box, and the best position for placing the bottom hooks is to pull up the bottom of all the cardboard smoothly, and the broken line cannot be skewed. When laying the cardboard and placing the lock bottom hook, the position of the upper paste wheel must be taken into account to avoid the position of the paste wheel occupied by the upper pressure paper tape and the bottom stick hook, and to avoid the big problem that the bottom can be hooked but cannot be pasted. It should also be noted that after the cardboard is bent, it must be pressed with a paper pressing rod in time to prevent the cardboard from rebounding and the machine cannot be started. See picture 9

2. adjust requirement

The installation standard of the first hook and the third hook is: the left and right positions are in the middle of the third side of the bottom stick box and the tongue at the bottom of the fifth side box, and the upper and lower positions are to make the folding angle of the bottom stick hook 2-3 mm higher than that of the paper box. The second hook has two sets of bottom hook accessories with the same installation standard. Select the wide or narrow bent cardboard according to the size of the carton. First install the bent cardboard, which is 2-3 mm higher than the carton, and its left and right positions are 2/3 places where the bent cardboard presses the adhesive surface on the bottom of the bottom stick box. Then adjust the upper and lower positions of the bottom stick hook to make the corner of the bottom hook be 2-3 mm higher than the carton, and adjust the left and right positions to the middle of the two sides of the bottom stick box. Then adjust the distance between the bottom sticker hook and the bent cardboard according to the position of the bent cardboard. The two coordinate: the corner of the bottom sticker hook is at the paper cutting position of the straight line and arc of the bent cardboard. When the bottom of the carton is pulled up and bent by the bottom sticker hook, the pressboard shall immediately bend the bottom of the carton. At the same time, the position of the lower cardboard holder should also be adjusted so that the bottom pasting box can be strongly supported when it is hooked. The special paper pressing rod should also be installed to prevent the folded cardboard from springing back after leaving the bottom pasting hook and the pressboard. After the paste is applied through the upper paste wheel, the folded cardboard can be smoothly fed into the folding part for folding.

3. upper glue pots lifting adjustment

The quality of the bottom pasting operation is not only related to the bending quality of the bottom of the cardboard, but also an important part of the assessment of the quality of the bottom pasting box. When all the bottom hook accessories are adjusted in place, turn the hand wheel to lower the pasting cylinder until the upper pasting wheel contacts the cardboard. According to the paper thickness and paperboard elasticity, the upper pasting wheel should be slightly lower or higher than the paperboard mouth (deviation ± 0.5mm), which can ensure reliable paste and smooth paper feeding. Turn the hand wheel to lower the upper paste cylinder until the positioning block contacts the adjusting block.

In order to ensure the paste quality, the paste shall be added at any time according to the paste consumption, and the adjustment screw shall be rotated forward and backward to change the amount of paste on the paste wheel.

After daily work, loosen the screws to quickly remove the upper paste cylinder, pour out the remaining paste, thoroughly clean the paste cylinder and paste wheel, and then apply a thin layer of butter after wiping to facilitate the next cleaning.

To sum up, the bottom pasting operation is relatively complicated. In addition to training and learning, the bottom pasting operation technology mainly depends on future practice. Through actual operation, more experience can be accumulated to properly handle various problems with no effort.

Because the bottom pasting operation needs to complete a series of actions such as pulling up, bending, sizing and pressing the bottom of the carton in a short process. The speed of the machine should be relatively slow compared with the side pasting, which is about 40-60% of the side pasting, to avoid tearing the carton too fast. Of course, the paper box is better, and the operator can be skilled without this limitation. In a word, the speed should be on the premise of no waste products.

really good article.

Великая статья.

A rare and good article

Hey. I am looking forward to your next share.

Helpful blog. I recommend it to my colleagues.

this article teaches me knowledge about box gluing machine. thanks a lot.

I learned a lot from this article.

perfect.I am benefitted a lot.

nice blog. I support it!

really good article. It’s useful.

It helps me to finish graduation thesis.

Create Your imagination. very nice article.

amazing article. I like it.

I learned a lot of how to adjust high speed automatic folder gluer for lock bottom box. thanks

Useful article.

this is one of the best blogs I read.

Folder Gluer Machines Manufacturer – Zhantian Folder Gluer – Best Article!

Folder Gluer Machines Manufacturer – Zhantian Folder Gluer

Hello guys! Nice Article!

I bought ZHANTIAN folder gluer machine before. It’s really a perfect machine. The service is awesome.

I’ve been exploring for a little for any high quality articles or blog posts on this kind of area . Exploring in Yahoo I at last stumbled upon this web site. Reading this information So i am happy to convey that I have an incredibly good uncanny feeling I discovered just what I needed. I most certainly will make sure to don’t forget this site and give it a look regularly.

great blog. I like it.

Hello guys! Nice article Folder Gluer Machines Manufacturer – Zhantian Folder Gluer

I really like this article. thanks for the auther

thanks for the arthur. I learned a lot.

very helpful article

helpful blog and nice article

I like this blog. thanks for the auther