Choose the suitable Folder-Gluer

People are perplexed in searcher of Folder-Gluer machines. There are hundreds of automatic folder gluer machines with different styles and functions on the market. In the eyes of inexperienced people, these devices are the same. But in the view of insiders, they can see the difference in quality at a glance. They usually need to consider the following questions when end users want to replace new machines or purchase new equipment.

I. What material do you run? Paperboard or corrugated?

The boxes on the market are made of cardboard, corrugated paper and PEP materials. The first two materials are more widely used. Cardboard is the general name of a kind of thick paper between paper and paperboard. It is usually used to produce boxes commonly used in daily life, such as medicine boxes, cosmetics boxes, and food boxes and so on. Corrugated paper is also called corrugated paperboard. It is formed by bonding at least one layer of corrugated paper and one layer of box board paper (also known as box board), which has good elasticity and extensibility. In the previous article, I compared the two kinds of paper. Please refer to this article for details.

For the Folder-Gluer of these two materials, the machine looks similar. In fact, the structure is completely different. Can the two materials be combined? The answer is not sure. The folder gluer machine can be applied to card cartons and micro corrugated boxes at the same time. Large box pasting machine is suitable for A / B corrugated, which is called corrugated folder gluer machine in the industry. If you have to use the card box pasting machine to produce large corrugated boxes, this can also be achieved, but the quality of the finished products is not high. If there is a sufficient budget, we recommend that users purchase a suitable folding gluing machine.

II. Product style

There are many custom cartons on the market, such as French fries box, sock box, box in box, etc. These boxes are different from medicine boxes. Their structures tend to be complex. For this type of box, folder gluer machine needs special modification. This may increase the length and width of the machine and require a larger site. In addition, the price of the machine will be raised.

Engineers will design targeted devices according to the special box type to complete this action. Of course, the special box pasting machine can complete the work of the conventional box. When making a special box, the mechanic needs to install the specific device in the specified position. When making a conventional box, remove this special part and it can work normally. The output of special box type is often lower than that of normal box type because of the complexity of its structure and the diversity of its actions. If economic conditions permit, it is recommended to purchase a separate box Folder-Gluer to produce these special boxes. It can be produced separately from ordinary box type to improve its production capacity.

When purchasing a new machine, its performance should be considered; when purchasing the second mobile phone, in addition to the performance, the age should also be considered. The box pasting machine used under normal conditions can work for 7-8 years. The older the aircraft, the higher the maintenance cost. Another important consideration is its functionality. For example, the existing machine in the factory is folder gluer machine for straight line box. It can’t be modified to do lock bottom box. The boss has to purchase a new machine for this project. It’s not a small expense.

Another key factor is the mechanical operator. Nowadays, experienced and skilled operators are scarce. A good operator can produce more boxes by adding different accessories. He can perfectly control the folder gluer machine to achieve the maximum output value and the highest utilization rate. A careful and patient mechanic can judge whether the machine is working properly by observing the operation of each part of the machine and listening to subtle sounds. If any abnormal condition is found, the technician can repair it through debugging in time, so as to prolong the service life of the machine.

As I mentioned above, the structure types of color boxes are ever-changing. This is a big challenge for mechanical operators. They need to constantly improve their own technology to keep up with the industry’s updating iterations. If their company wants to enter a new market, they also need to learn to operate a new Folder-Gluer. The operation method of the folder gluer machine with different functions is also different. Despite their superb skills, this is also a difficult task.

III. Start based on budget

The price of the Folder-Gluer ranges from $5000 to $100000. Folder gluer machine with lower price can produce boxes with simple structure. Similarly, the box folding gluing machine with higher price can produce boxes with complex structure and various changes. The price of the machine increases with the increase of its functionality, but this kind of equipment is more mobile and has more development prospects.

The pricing of box pasting machine is affected by the following factors: 1 Manufacturer’s brand. The higher the brand value, the higher the equipment price. 2. Machine process. The whole machine adopts laser cutting process, which is more accurate than manual cutting, and the edge treatment is more careful. 3. Performance and function. The performance of a machine refers to its stability during operation. The more comprehensive a machine is the more work it can accomplish. 4. Market supply and demand relationship. 5. Price of raw materials. In addition to the items I have listed above, the price of the machine may also be affected by some force majeure factors, such as the worldwide spread of viruses.

Early market research is very necessary. Buyers need to analyze the advantages and disadvantages of each machine. Before purchase, negotiate with the manufacturer to see if there are any hidden expenses and check if the quotation includes transportation cost, installation and commissioning cost. The costs of later maintenance and parts replacement should also be confirmed in advance.

From the technical point of view, the following options can be made.

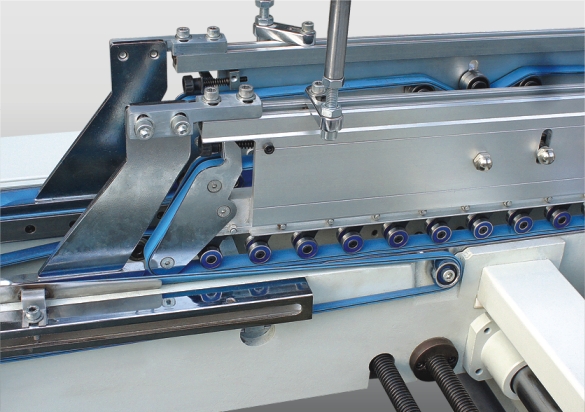

Firstly, considering the switching of different box types, there are manual versions and automatic versions on the market. The manual version means that the technical workers move the folding row to the best position by hand. This kind of machine depends on the technology and experience of workers, and it is time-consuming to adjust the machine. Automatic version is to identify products through a system. After recognition, the system sends out instructions to move the folding row to the most appropriate position. The system will record the box type and size. The next time when the box is encountered, the system can quickly identify it and enter the pending production state. This not only saves time, but also improves the accuracy and can make high-quality products.

This version of the machine is easy to operate, and anyone who does not know the technology can operate it. This reduces labor costs for enterprises. But the cost of equipment has increased. Compared with the former, the price of this kind of machine will be twice or even three times higher. Therefore, buyers need to consider their daily demand and output. If it is not very high, I would prefer to buy the product with high cost performance of the former. Large scale factories are suitable for automatic Folder-Gluer machines.

In addition to the options I mentioned above, there is another compromise option. Users can purchase an analysis system with memory. Before producing a new box product, the user places the box on the scanner provided by the system for detailed scanning. After identifying the specific size, the system will give accurate data. The technical engineer shakes the folding row to the corresponding position according to these data. In this way, the adjustment is completed. Compared with the traditional manual rocking arrangement, the use of system data can reduce the test time and save paper. Compared with relying solely on system commissioning, this scheme has lower investment cost and less risk. It is more in line with the public consumption level.

To sum up, the selection of box pasting machine is based on product and budget. In addition, it is also necessary to consider the subsequent packaging issues, such as how to bind the pasted cartons and how to pack the bound cartons. On these issues, I will write a separate article to explain it later.

ZHANTIAN is a trustworthy supplier in China for Folder-Gluer machines. We have 17 years’ experience in this field. Visit website to learn more: www.zhantianfoldergluer.com

Greetings! Very useful advice within this article! It is the little changes that produce the most significant changes. Thanks for sharing!

helpful blog

good article