How to select a folder gluer machine

I. reasons of purchasing a box pasting machine

In the packaging and printing industry, the application of box pasting machine is one of the later processes of packaging box processing. It is to fold and paste the printed and die-cut paperboard. The machine box pasting replaces the manual box pasting method, which reduces the labor cost and improves the efficiency. But now many paper packaging factories are still hesitant to start the box pasting machine. Today, we will bring you several reasons why you should buy it.

-

High productive and low energy consumption

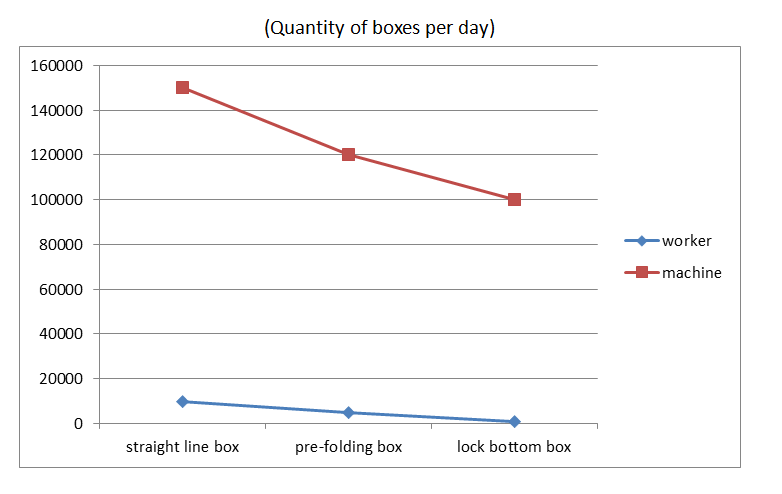

Color boxes, express boxes and other packaging boxes are very common and practical in people’s daily life. In other words, people’s life is inseparable from the packaging industry. For this high demand product, more than ten years ago, it was produced manually. This mode of production is not only inefficient but also high consumption. The defective rate of finished products produced is high, the broken lines are not aligned, and there is a bell mouth. The capacity of the machine is 15-20 times that of the labor. Get more benefits in a shorter time. After careful research and investigation, I made a performance comparison table as follows

-

Less cost and high return

The high production capacity of the box pasting machine is indisputable. The value created by the machine far exceeds its price. According to the gross profit of 0.01 yuan for one side pasted box, the machine can complete 35000 boxes in one hour, work for 8 hours a day, and the gross profit in one day is 0.01 * 35000 * 8 = 2800 yuan. The gross profit of pre folded hook bottom box and special-shaped box is much higher than that of ordinary edge paste box. The price of an ordinary box pasting machine is 40000 yuan. According to this plan, we can get back to our capital in 14 days. The average working life of a box pasting machine is about 8-10 years. Therefore, the box pasting machine is a kind of equipment with high production capacity and low investment.

II. How to select an ideal box gluing machine

What factors and indicators should packaging and printing enterprises pay attention to and consider when purchasing automatic box pasting machine? What should I pay attention to? The function of automatic box pasting machine is one of the important factors considered by users. If the function is too simple, there will be nothing to do when encountering products with slightly more complex box type, which will inevitably affect the expansion of business.

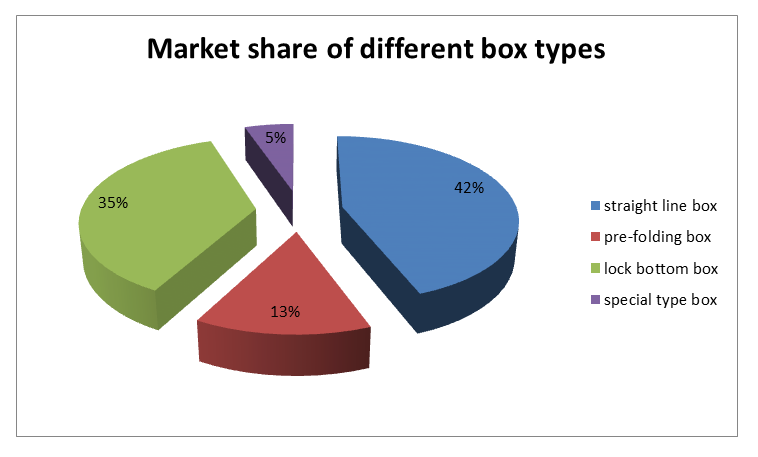

The box pasting machine is divided into three categories: ordinary edge pasting machine, pre folding machine and bottom hook machine. It is applicable to ordinary side paste box, pre folding box and bottom hook box respectively. The market share of these three box types is as follows.

As the saying goes, “shop around”, packaging and printing enterprises are no exception when purchasing automatic box pasting machines. After all, equipment investment is a major event, which has an important impact on the future development of enterprises. So, what factors and indicators should packaging and printing enterprises pay attention to and consider when purchasing automatic box pasting machine? What should I pay attention to?

According to the information, packaging and printing enterprises mainly consider the function, format, price, speed, stability and other indicators of the automatic box pasting machine when purchasing the automatic box pasting machine.

The function of automatic box pasting machine is one of the important factors considered by users. If the function is too simple, there will be nothing to do when encountering products with slightly more complex box type, which will inevitably affect the expansion of business. Of course, the more functions of the equipment, the higher the price. “You can’t have both fish and bear’s paw”. Therefore, on the premise of meeting the product demand, the price of the automatic box pasting machine should also be considered, that is, the equipment with high cost performance should be selected.

Users are also very concerned about the stability and reliability of the automatic box pasting machine, and require the automatic box pasting machine to operate stably and reliably with low failure rate. If the performance of the automatic box pasting machine is unstable and often fails, it will not only affect the production and delay the delivery date, but also damage the reputation and image of the enterprise.

In addition to the above indicators, packaging and printing enterprises should also pay attention to the following matters when purchasing automatic box pasting machines.

-

We must clarify the enterprise’s own product positioning and combine it with the enterprise’s long-term planning.

We should not blindly follow. If we see a certain type of automatic box pasting machine introduced by other enterprises, regardless of 3721, we also buy this type of equipment ourselves; it is likely to be unsuitable or unable to meet the production requirements of our enterprise. Or some enterprises blindly pursue high-grade, do not consider their own economic strength and business situation, and do not hesitate to spend a lot of money to introduce high-grade automatic box pasting machines from abroad, which is likely to make high-grade equipment low-grade use, resulting in a waste of funds and resources.

-

Clear the products produced by the enterprise

If the box type produced by the enterprise is relatively simple, you can choose an automatic box pasting machine with simple function, and the price is relatively cheap; If you need to process products with complex box types, such as lock bottom box, double wall box, hexagonal box, octagonal box and special-shaped box, you need to buy a box pasting machine with complete functions to cover the range of products produced.

There are many format specifications of automatic box pasting machine. For example, zhantian ZH series automatic box pasting machine has three format specifications of 450mm, 600mm and 1000mm. The larger the format is, the better. According to the basic dimensions and specifications of the packaging boxes produced by the enterprise, determine and select the appropriate automatic box pasting machine.

-

We must also pay attention to the after-sales service and technical support ability of equipment suppliers.

If the after-sales service and technical support of the automatic box pasting machine supplier can’t keep up, once the equipment has problems and can’t get the technical support of the manufacturer in time, it will affect and delay the production cycle, which can be said that the gain is not worth the loss. For the majority of packaging and printing enterprises, the strong technical strength and perfect after-sales service system of automatic box pasting machine manufacturers are of great significance to the sustainable development of enterprises in the future. Therefore, it is very important to find the right partners.

III. How to operate a box folding gluing machine

-

Preparation part

(1) Confirm if the product can be made by the machine.

(2) Put semi-finished box pieces tidily and correctly.

(3) Check all parts of machine running well.

(4) Based on paper width, adjust the glue volume.

-

Adjusting process

(1) Move feeding belts to correct position to be suitable for the product.

(2) Turn off folder gluer machine if there is a problem of die-cutting line.

(3) Make every part to precise position to ensure the product worked well.

(4) Lock bottom hooks must be installed suitably when doing lock bottom boxes.

(5) Set conveyor pressure to achieve best result.

-

Finishing work

(1) Write work report

(2) Sweep the workshop.

(3) Uninstall glue pots and wash it.

(4) Turn off the machine and cut off the electricity.

IV. Maintenance

Maintenance plays an important role in folder gluer machine lifetime. Correct and suitable maintenance can extender service life. Conversely, its use time is short. The cost increased and profit narrowed. What’s appreciated maintenance? Firstly, select a responsible and competent man as the manager to be in charge of daily running of the folder gluer machine. Secondly, the technician must learn about the manual book carefully and earnestly when operating the machine for the first time. Normal training can be offered to the technicians as well as machine use requirements if time and fund allowed. Operators are familiar with machine performance and know how to run it through the training, which can avoid many mistakes in the future. Machine specification is also important to be learned by technicians. Besides, factories needs to set up supervise team to inspect and manage machine using. It’s necessary to take restrictive measurements to keep the machine running under correct operation. Glue pots on the machine must be cleaned every day after working. And machine should be cleaned up often, especially mechanical belts. They are slipping and sticking if glue is on them. In addition, bearing rubber wheels and lock bottom hooks are also need to be washed daily. They become freezing when glue dries. The other parts of the machine are supposed to be washed one time a week. I want to advise a good measure to avoid being rust. Operators can mix lubricating oil and butter. Then brush them to the machine. It’s good antirust oil.

Finally, it’s astrictive to run the machine with available speed. Over-loading is forbidden because governor and belts are seriously broken. It’s better to run the machine under middle speed the protect it. Machine is supposed to be operated at low speed to check if it can work well. Debugging is also done under low speed.

V. Type of folder gluer machine

There are many kinds of box pasting machines. How should people choose when purchasing? Generally speaking, the type of machine is selected according to the box structure, material, size, etc.

-

Common classification

The most common pasting machines are divided into two categories: one is the side pasting machine, also known as unilateral gluing machine; The second is the bottom gluing machine, also known as the 3-point gluing machine. As the name suggests, the side paste box machine is suitable for glued boxes on one or both sides, such as medicine boxes, cosmetics boxes, etc. For the box with hook bottom, it is common in toy box, mask box, etc. In addition, pre folding paste box machine is also very common. The pre folded box can be used with the packing machine in the subsequent packing process. Otherwise, the articles can only be put in manually and sealed. Large factories often need pre folding and pasting machines to improve production capacity, reduce labor costs and make more accurate and perfect products.

-

Heterosexual box gluing machine

In addition to several common box types, some heterosexual boxes will appear on the market to match the packaging of products. Common heterosexual boxes include popcorn box, French fries box, CD box, room card sleeve, etc. For these special boxes, the factory designs and produces specific models to complete the paste work of these boxes. The box pasting machine suitable for French fries box is called French fries box pasting machine. The box pasting machine suitable for room card sleeve is called room card sleeve box pasting machine. For these special boxes, different factories have different machine structures and practices. When selecting machines, printing plants need to comprehensively consider many aspects and select the machines with the highest cost performance.

VI. Conclusion

With the rapid development of packaging industry, the introduction of box pasting machine is essential. How to choose the best machine and equipment has become a key problem. This paper expounds the reasons and dimensions of procurement, and expresses some personal views. The input value of a piece of equipment ranges from tens of thousands to hundreds of thousands of CNY. For many buyers, this is not a small expense. Manufacturers with good equipment quality and excellent service attitude should be carefully selected. With good equipment, the buyer can get back the capital and make a profit quickly. Therefore, before purchasing equipment, we should fully understand the market situation, calculate the input-output ratio, and strive to maximize benefits.

Greetings! Very useful advice within this article! It is the little changes that produce the most significant changes. Thanks for sharing!

good article

i know how to select folder gluer now. thanks